-

call us

022 23857766 \ 022 67437326 -

send us mail

sales@globalstainless.co.in

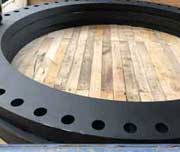

ASTM A694 F52 Flanges

Carbon Steel A694 F52 Material

SA694 Gr F52 Elbow

| Carbon [C] | ≤0.30 |

| Manganese [Mn] | ≤1.60 |

| Phosphorus [P] | ≤0.025 |

| Sulfur [S] | ≤0.025 |

| Silicon [Si] | 0.15-0.35 |

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SA 694 F52 | 415 | 315 | 20 % |

| ASTM A694 Grade | Yield Strength min. | Tensile Strength min. | Elongation min. | ||

| MPa | ksi | MPa | ksi | % | |

| A694 Grade F52 | 360 | 52 | 455 | 66 | 20 |

| Specification : | ASTM A694 F52 Flanges |

| Design For Size: | ASME, DIN, JIS, ANSI, BS, PN, EN, ASA |

| Flange Machining Equipment: | Bending machine, Pushing Machine, electric bevelling machine Sand-blasting machine, Press machine etc |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Standards: | UNI Flanges, AWWA Flanges, MSS SP44 Flanges, ASME B16.5 Flanges, ASME B16.47 (Series A, Series B) GOST Flanges, ASME B16.38 Flanges, EN-1092 Flanges, BS10 Flanges, DIN Flanges, PN Flanges, JIS Flanges, ISO Flanges |

| Production Process: | Machined, Forged, Heat Treated |

| Application: | Fabrication Industry Natural Gas Industry Chemical Industry Oil And Gas Industry Water Pipeline Industry Nuclear Power Plant |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Coating Flange Faces : | Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized, Oil Black Paint, Anti-rust Paint |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

High Yield Carbon Steel F52 RTJ Flanges

Steel Grade F52 Raised Face Flanges

A694 CS Gr F52 Socket Weld Flanges

Grade F52 Carbon Steel Slip On Flanges

ASTM A694 Gr F52 Reducing Flanges

A694 F52 Weld Neck Flanges

SA 694 F52 Blind Flanges

Carbon Steel A694 Grade F52 Flat Face Flanges

ASME SA 694 F52 Threaded Union

ASTM A694 F52 Steel Threaded Hex Plug

Carbon Steel A694 F52 90 Deg Elbow

Carbon Steel ASME SA694 F52 Socket Weld Tee

| Temp. °C | Pressure Range | ||||||

|---|---|---|---|---|---|---|---|

| 150 | 300 | 400 | 600 | 900 | 1500 | 2500 | |

| -29 ~ 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233.0 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219.0 | 365.0 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313.0 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23.0 | 30.7 | 46.0 | 69.0 | 115.0 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

NPS |

Flanges (ID) (inch) |

Flanges (OD) (inches) |

||||

| 150 LB | 300 LB | 400 LB | 600 LB | 900 LB | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

| Standard | Class | Dia. | Bolt Circle Dia. | No. of Bolts | Bolt Size | Dia. of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

| Alloy Steel 2129 Flange | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |