-

call us

022 23857766 \ 022 67437326 -

send us mail

sales@globalstainless.co.in

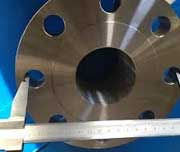

| Specification : | ASTM A182 F5 Flange |

| Flange Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Dimensions Class: | 2000# Fittings, 3000# Fittings, 6000# Fittings, 9000# Fittings |

| Production Process: | Forged, Heat Treated and Machined |

| Coating Flange Faces : | Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized, Oil Black Paint |

| Forged Type : | NPT (Threaded) Fittings, BSPT Fittings, BSPP Fittings. |

| Connect Type Type: | RTJ Flange, LMF Flange, SMF Flange, LJF Flange, RF Flange, FF Flange |

| Design For Size: | ASME Flange, DIN Flange, JIS Flange, EN Flange, ASA Flange, ANSI Flange, BS Flange, PN |

| Pressure: | Check Pressure Rating Of Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Standards: | MSS SP44 Flange, ASME B16.38 Flange, EN-1092 Flange, BS10 Flange, DIN Flange, PN Flange, JIS Flange, ISO Flange, GOST Flange, UNI Flange, AWWA Flange, ASME B16.5 Flange, ASME B16.47 (Series A, Series B) Flange |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Common Types of Flange : | Flanges 150 LB WNRF Class 300 RTJ 600# BLRF Class 900 SORF |

| Application: | Oil And Gas Industry Water Pipeline Industry Nuclear Power Plant Fabrication Industry Natural Gas Industry Chemical Industry |

| Material Group | Common Name | Type | UNS | Forging Spec. | Casting Spec. Equivalent | DIN |

|---|---|---|---|---|---|---|

| 5Cr-1/2Mo | K41545 | A182-F5/F5a | A217-C5 | 12CRMO195 | 1.7362 | High temp refinery service |

Alloy Steel F5 Reducing Flange

Alloy Steel A182 F5 Weld Neck Flange

Steel A182 Gr F5 Blind Flange

ASTM A182 Grade F5 Flat Face Flange

Alloy Steel SA 182 Gr F5 Steel RTJ Flange

Alloy Steel A182 Grade F5 Raised Face Flange

AS A182 F5 Socket Weld Flange

Steel A182 F5 Alloy Steel Slip On Flange

Alloy Steel F5 Forged 90 Degree Elbow

Alloy Steel A182 F5 Socket Weld Cap

SA182 F5 Forged 45 Degree Elbow

ASTM A182 Gr F5 SW Full Coupling

| Grade | C | Mn | Si | S | P | Cr | Mo |

| ASTM A182 F5 Flanges | 0.15 | 0.3 - 0.6 | 0.5 | 0.03 | 0.03 | 4 - 6 | 0.044 - 0.65 |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| SA182 Gr F5 | 275 | 485 | 20 |

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature °F | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -20 to 100 | 265 | 695 | 925 | 1390 | 2085 | 3470 | 5785 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5660 |

| 300 | 230 | 655 | 870 | 1305 | 1955 | 3260 | 5435 |

| 400 | 200 | 640 | 855 | 1280 | 1920 | 3200 | 5330 |

| 500 | 170 | 620 | 830 | 1245 | 1865 | 3105 | 5180 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | 50 | 450 | 600 | 900 | 1350 | 2245 | 3745 |

| 950 | 35 | 280 | 375 | 560 | 845 | 1405 | 2345 |

| 1000 | 20 | 165 | 220 | 330 | 495 | 825 | 1370 |