-

call us

022 23857766 \ 022 67437326 -

send us mail

sales@globalstainless.co.in

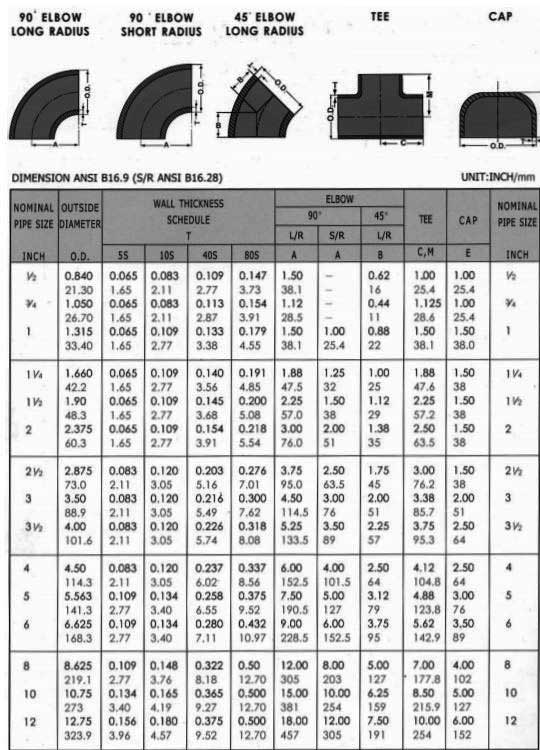

| Standard Specification : | Stainless Steel Buttweld Pipe Fittings |

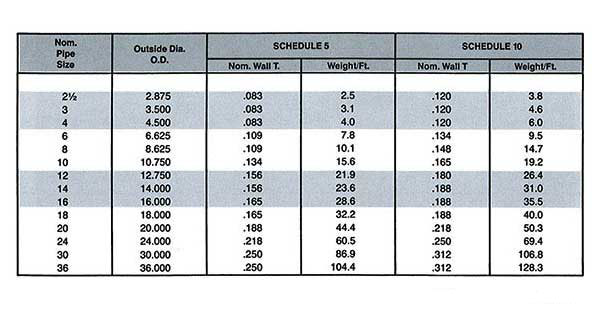

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | ANSI B16.9 Fittings, MSS-SP-43 Type A Fittings, MSS-SP-43 Type b Fittings, MSS-SP-43 Type B Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, JIS B2313 Fittings |

| Stainless Steel Fittings Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Coating Flange Faces : | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated |

| Fitting Machining Equipment: | Bending machine, Pushing Machine, Sand-blasting machine, Press machine, electric bevelling machine etc |

| Rating Pressure: | Check Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Application: | Oil And Gas Industry Nuclear Power Plant Natural Gas Industry Chemical Industry Fabrication Industry Water Pipeline Industry |

| Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| SS 100 | SS 200 | SS 300 | SS 400 | SS 500 | SS 600 | SS 650 | SS 700 | SS 750 | ||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

|

Ni

|

8 – 11

|

8 – 11

|

8 – 11

|

|

Fe

|

Balance

|

||

|

Cr

|

18 – 20

|

18 – 20

|

18 – 20

|

|

C

|

0.08 maximum

|

0.08 maximum

|

0.035 maximum

|

|

Si

|

0.75 maximum

|

0.75 maximum

|

0.75 maximum

|

|

Mn

|

2 maximum

|

2 maximum

|

2 maximum

|

|

P

|

0.040 maximum

|

0.040 maximum

|

0.040 maximum

|

|

S

|

0.030 maximum

|

0.030 maximum

|

0.030 maximum

|

|

N

|

0.10 – 0.16

|

0.10 – 0.16

|

|

| NPS | OD | 90 Degree Elbow | 45 Degree Elbow | 180 Degree Returns | ||||

|---|---|---|---|---|---|---|---|---|

|

(in.)

|

LR

|

SR

|

LR

|

LR

|

||||

|

(millimeter)

|

(in.)

|

Center to Face

(in.) |

Center to Face

(in.) |

Center to Face

(in.) |

Radius

(in.) |

Center to Center

(in.) |

Back to face

(in.) |

|

|

1/2

|

21.3

|

0.840

|

1 1/2

|

–

|

5/8

|

2

|

1 7/8

|

|

|

3/4

|

26.7

|

1.050

|

1 1/8

|

–

|

7/16

|

2 1/4

|

1 11/16

|

|

|

1

|

33.4

|

1.315

|

1 1/2

|

1

|

7/8

|

3

|

2 3/16

|

|

|

1 1/4

|

42.2

|

1.660

|

1 7/8

|

1 1/4

|

1

|

3 3/4

|

2 3/4

|

|

|

1 1/2

|

48.3

|

1.900

|

2 1/4

|

1 1/2

|

1 1/8

|

3

|

4 1/2

|

3 1/4

|

|

2

|

60.3

|

2.375

|

3

|

2

|

1 3/8

|

4

|

6

|

4 3/16

|

|

2 1/2

|

73.0

|

2.875

|

3 3/4

|

2 1/2

|

1 3/4

|

5

|

7 1/2

|

5 3/16

|

|

3

|

88.9

|

3.500

|

4 1/2

|

3

|

2

|

6

|

9

|

6 1/4

|

|

3 1/2

|

101.6

|

4.000

|

5 1/4

|

3 1/2

|

2 1/4

|

7

|

10 1/2

|

7 1/4

|

|

4

|

114.3

|

4.500

|

6

|

4

|

2 1/2

|

8

|

12

|

8 1/4

|

|

5

|

141.3

|

5.563

|

7 1/2

|

5

|

3 1/8

|

10

|

15

|

10 5/16

|

|

6

|

168.3

|

6.625

|

9

|

6

|

3 3/4

|

12

|

18

|

12 5/16

|

|

8

|

219.1

|

8.625

|

12

|

8

|

5

|

12

|

24

|

16 5/16

|

|

10

|

273.1

|

10.750

|

15

|

10

|

6 1/4

|

15

|

30

|

20 3/8

|

|

12

|

323.9

|

12.750

|

18

|

12

|

7 1/2

|

18

|

36

|

24 3/8

|

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile St. | Psi – 75000 , MPa – 515 |

| Yield St. (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Hs Code | Description | Number Of Shipments |

|---|---|---|

| 7307 | Tube Or Pipe Fitting (Half, Full Couplings, 45, 90, 180, Elbows,) | |

| 73072900 | Other | 11954 |

| 73079990 | Other | 1350 |

| 73072200 | NPT Elbows, Sleeves And Bends | 482 |

| 73072300 | BW Fitting | 384 |

| 73079190 | Other |