-

call us

022 23857766 \ 022 67437326 -

send us mail

sales@globalstainless.co.in

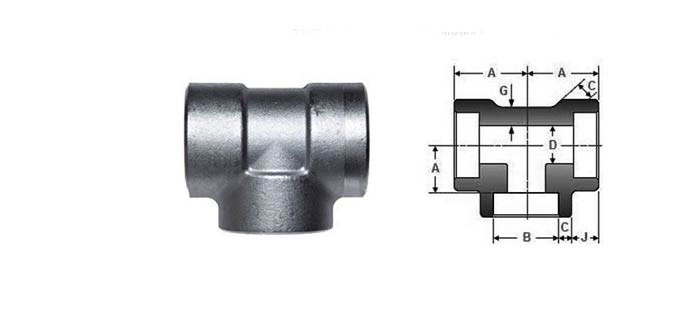

| Specification : | ASME B16.11 Reducing Tee |

| Size: | 1/8” NB to 4” NB (Screwed-Socket) |

| Forged Type : | NPT (Threaded), BSPT, BSPP. |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Standard: | JISB2311, IS 2062, DIN, ANSI B16.28, ASME B16.9, BS10, ASME B16.47, ASME B16.38, MSS-SP-43, JISB2313, ASME B16.25, MSS SP-75, DIN2605, JISB2312, PN, AWWA C207, BS4504, BS1560, BS, GB, ISO |

| Connection Type : | Welding |

| Pressure Rating: | Socket, Threaded: 3000 LBS, 6000 LBS, 9000 LBS |

| Mills And Origin : | Europe, Russian, USA, India, Japanese |

1 X 1/2 NPS Socket Weld Reducing Tee

2 X 1 NPS 3000# ASME B16.11 Reducing Tee

3/4 To 1/2 NPS 6000# Forged Reducings Tee

3/6 x 1/2 9000# Socket Weld Unequal Tee

1-1/2 inch 6000# 304L Stainless Steel Socket Weld Reducing Tee

1/2 inch Class 6000 Socket Weld Reducing Tee

ASTM A182 SS Socket weld Reducing Tee

10 x 10 Weld Sch 10 Threaded Pipe Reducing Tee

1/2 To 1/2 Inch Carbon Steel Threaded Reducing Tee

1/2 To 1/2 Inch 3000# Threaded Reducing Tee

2 inch Sch 40 Stainless Steel Threaded Reducing Tee

1/2 To 2/3 Inch Forged Threaded Reducing Tee

| Normal Pipe Size | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| NPS | Socket WT |

Body WT |

Center to bottom of socket |

| C | G | A | |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

| NPS | B | L1 | C | G | D | A | Weight |

|---|---|---|---|---|---|---|---|

| inch | MilliMeter | socket | MilliMeter | MilliMeter | MilliMeter | MilliMeter | ~Kilogram/pce |

| 1/4 3/8 1/2 3/4 |

14.20 17.60 21.80 27.20 |

9.53 9.53 9.53 12.50 |

3.30 3.51 4.09 4.27 |

3.02 3.20 3.73 3.91 |

8.86 12.14 15.42 20.55 |

11.11 13.49 15.88 19.05 |

0.11 0.16 0.34 0.41 |

| 1 1¼ 1½ 2 |

33.90 42.70 48.80 61.20 |

12.50 12.50 12.50 16.00 |

4.98 5.28 5.54 6.05 |

4.55 4.85 5.08 5.54 |

26.26 34.67 40.51 52.12 |

22.23 26.99 31.75 38.10 |

0.65 0.95 1.33 2.20 |

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

| Nirmal Pipe Size | Minimum Length of Thread | Outside Dia of Band D |

Center to End A |

Minimum WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

| #2000 | NPS | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.740 | 1.058 | 1.375 | 1.740 | 2.883 | 7.750 | 11.313 | 19.125 | |

#3000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.250 | 0.290 | 0.500 | 0.750 | 1.188 | 1.988 | 2.235 | 3.000 | 4.930 | 7.375 | 13.588 | 19.063 | |

#6000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.250 | 0.640 | 0.500 | 1.438 | 2.188 | 2.785 | 4.688 | 5.750 | 9.500 | 15.000 | 30.563 | – | |

NPS |

1/2 to 2½ |

3 to 3½ |

4 |

5 to 8 |

10 to 18 |

20 to 24 |

26 to 30 |

32 to 48 |

Outside Dia |

+1.6 |

1.6 |

1.6 |

+2.4 |

+4 |

+6.4 |

+6.4 |

+6.4 |

Inside Dia at End |

0.8 |

1.6 |

1.6 |

1.6 |

3.2 |

4.8 |

+6.4 |

+6.4 |

Center to End (C / M) |

2 |

2 |

2 |

2 |

2 |

2 |

3 |

5 |