-

call us

022 23857766 \ 022 67437326 -

send us mail

sales@globalstainless.co.in

| Specification : | DIN 2501 PN10 Flange |

| Coating Flanges Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Zinc Plated, Oil Black Paint, Anti-rust Paint |

| Design For Size: | BS, DIN, ANSI, ASME, EN, ASA, JIS |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Standard : | BS10 Flange, DIN Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.38 Flange, ISO Flange, JIS Flange, MSS SP44 Flange, EN-1092 Flange, ASME B16.5 Flange, AWWA Flange, GOST Flange |

| Machining Equipment: | Press machine, Pushing Machine, Electric bevelling machine, Bending machine, Sand-blasting machine etc |

| Application: | Chemical Industry Water Pipeline Industry Natural Gas Industry Fabrication Industry Nuclear Power Plant Oil And Gas Industry |

| Supporting Flanges Material: | Ring Joint, Flanges Bolts, Gasket |

| Connect Type Type: | LMF, RF, LJF, FF, RTJ, SMF |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

| Common Types of Flanges Dimensions: | Class 150 RTJ Flanges 300 LB WNRF Class 900 SORF 1500# BLRF Class 2500 BLRF |

| Production Process: | Forged, Heat Treated and Machined |

DIN 2501 PN10 Plate Flange

DIN 2501 PN10 Slip On Flange

Din 2501 Flange Material

Flat Flange Din 2501 pn10

Flanges Norma DIN 2576 PN10

DIN 2576 PN 10 Form B Flange

DIN 2576 PN 10 DN 300 Flange

DIN 2501 PN10 Blind Flange

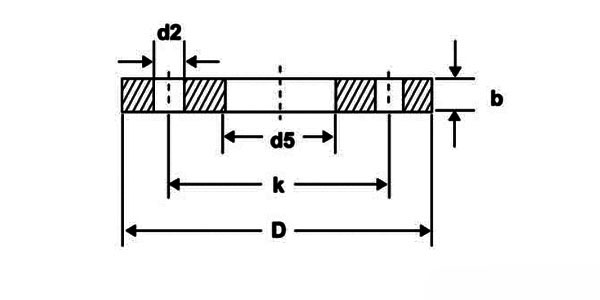

| NPS | Diam. of | Flanges Diameter | Flanges I.D | Thickness of Flanges | Diameter of Bolt Cirlce | Number of | Diameter of Bolt Holes | Weight | |

|---|---|---|---|---|---|---|---|---|---|

| PLATE | BLIND | ||||||||

| DN | Pipe | D | D5 | B | K | holes | D2 | KG | KG |

| 15 | 21.30 | 95 | 22.00 | 14 | 65 | 4 | 14 | 0.67 | 0.71 |

| 20 | 26.90 | 105 | 27.60 | 16 | 75 | 4 | 14 | 0.93 | 1.01 |

| 25 | 33.70 | 115 | 34.40 | 16 | 85 | 4 | 14 | 1.11 | 1.23 |

| 32 | 42.40 | 140 | 43.10 | 16 | 100 | 4 | 18 | 1.62 | 1.81 |

| 40 | 48.30 | 150 | 49.00 | 16 | 110 | 4 | 18 | 1.85 | 2.09 |

| 50 | 60.30 | 165 | 61.10 | 18 | 125 | 4 | 18 | 2.46 | 2.88 |

| 65 | 76.10 | 185 | 77.10 | 18 | 145 | 4 | 18 | 2.99 | 3.65 |

| 80 | 88.90 | 200 | 90.30 | 20 | 160 | 8 | 18 | 3.61 | 4.61 |

| 100 | 114.30 | 220 | 115.90 | 20 | 180 | 8 | 18 | 3.99 | 5.65 |

| 125 | 139.70 | 250 | 141.60 | 22 | 210 | 8 | 18 | 5.41 | 8.13 |

| 150 | 168.30 | 285 | 170.50 | 22 | 240 | 8 | 22 | 6.55 | 10.44 |

| 175 | 193.70 | 315 | 196.10 | 24 | 270 | 8 | 22 | 8.42 | |

| 200 | 219.10 | 340 | 221.80 | 24 | 295 | 12 | 22 | 8.97 | 16.48 |

| 250 | 273.00 | 405 | 276.20 | 26 | 355 | 12 | 26 | 12.76 | 23.99 |

| 300 | 323.90 | 460 | 327.60 | 28 | 410 | 12 | 26 | 16.60 | 30.73 |

| 350 | 355.60 | 520 | 359.70 | 30 | 470 | 16 | 26 | 24.08 | 42.56 |

| 400 | 406.40 | 580 | 411.00 | 32 | 525 | 16 | 30 | 30.20 | 60.68 |

| 450 | 457.00 | 640 | 462.30 | 38 | 585 | 20 | 30 | 41.67 | 71.74 |

| 500 | 508.00 | 715 | 513.60 | 38 | 650 | 20 | 33 | 52.87 | 96.4 |

| 600 | 610.00 | 840 | 616.50 | 42 | 770 | 20 | 36 | 77.58 | 145.6 |

| 700 | 711.00 | 910 | 716.00 | 44 | 840 | 24 | 36 | 77.13 | |

| 800 | 813.00 | 1025 | 818.00 | 50 | 950 | 24 | 39 | 106.35 | |

| 900 | 914.00 | 1125 | 920.00 | 54 | 1050 | 28 | 39 | 125.39 | |

| 1000 | 1016.00 | 1255 | 1022.00 | 60 | 1170 | 28 | 42 | 177.99 | |

| Temperature (in F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test (psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

| NPS NPS (inch) |

|||||

|---|---|---|---|---|---|

| Diammeter of Flanges (inch) |

No. of Bolts |

Diammeter of Bolts (inch) |

Diammeter of Bolt Holes (inch) |

Bolt Circle (inch) |

|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |